//

OUR PROUDCTS

European hot-rolled 15mm 76 Tie Rod Flat Bar – W/L 90 kN / Ultimate tensile load : 184 kNer

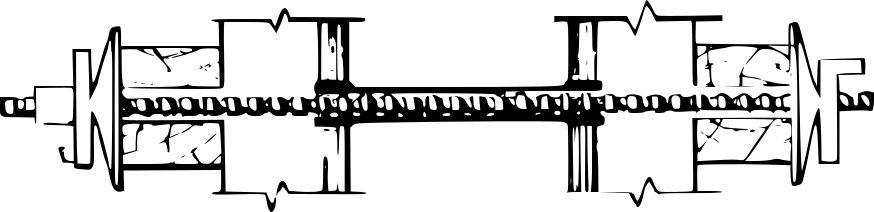

Tie rods are threaded rods that connect opposite formwork panels, ensuring they remain aligned during concrete pouring. They provide stability and prevent bulging.

Features

- nominal diameterTie rod with nominal diameter 15 mm

- Ultimate loadUltimate load no less than 188 kN

- Yield loadYield load 159 kN

- Working load Working load 100 kN

.15mmnominal diameter

.188kNUltimate load

.159kNYield load

.100kNWorking load

Dimensions and technical specifications

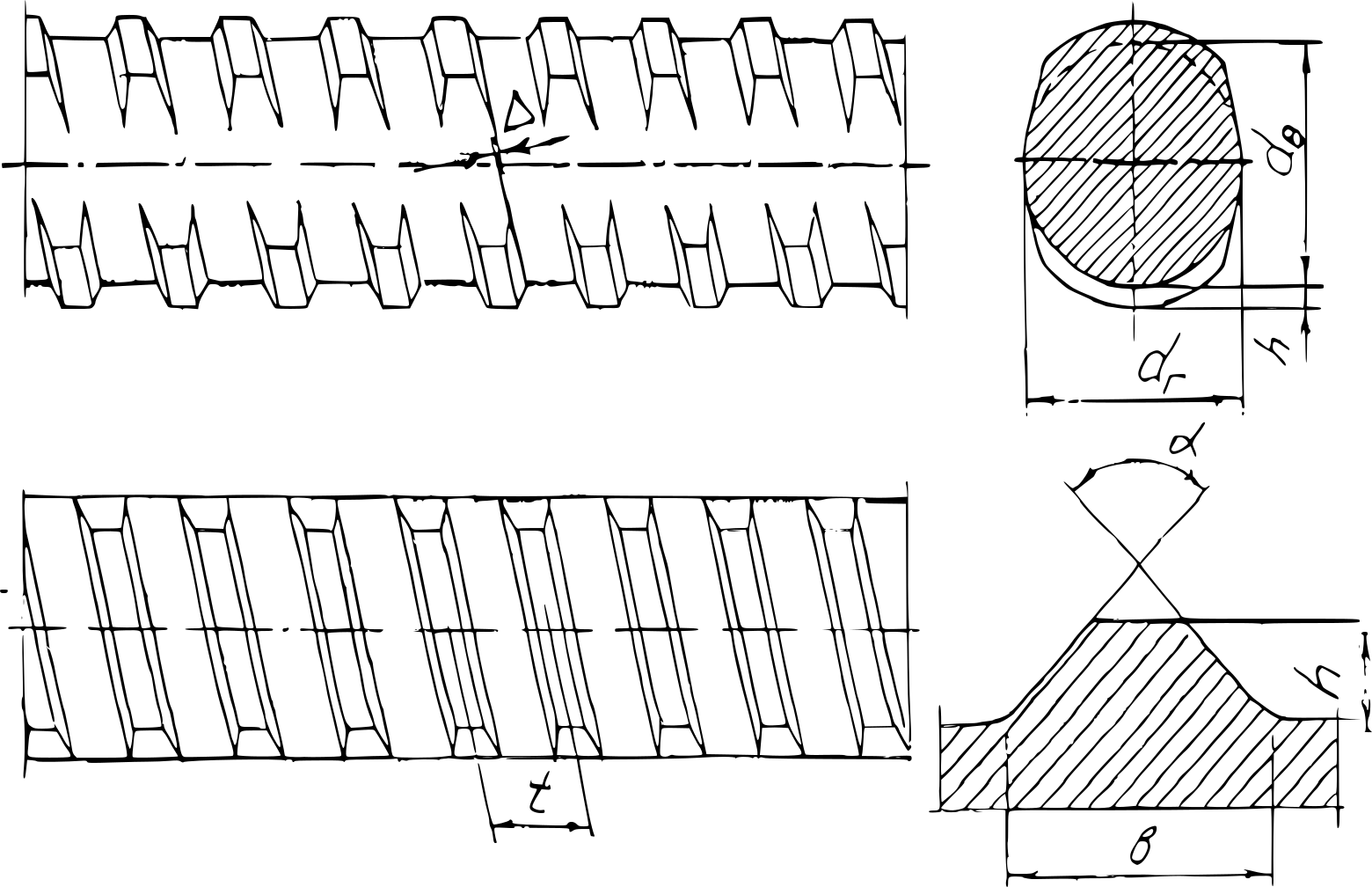

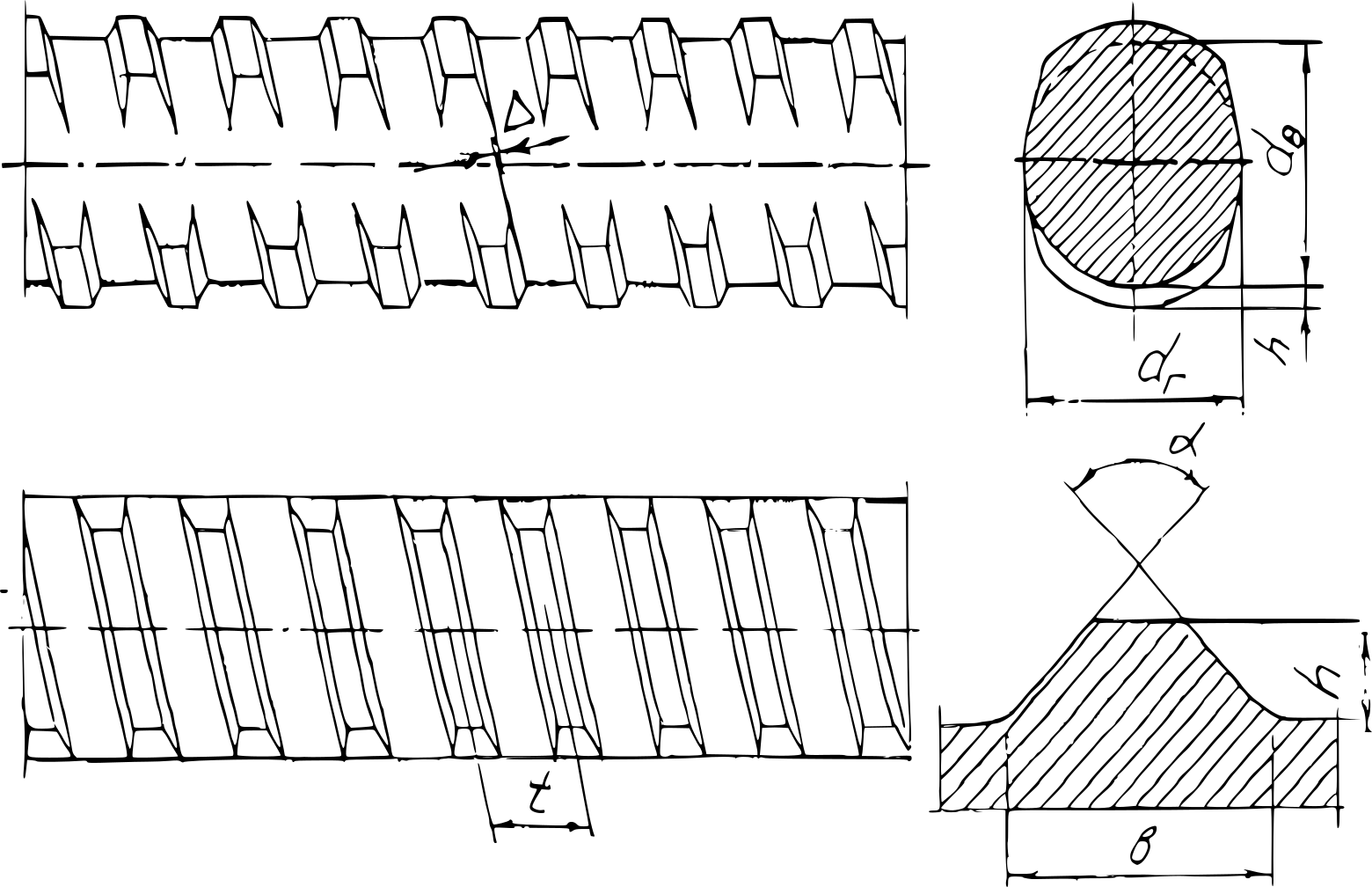

TYPES AND DIMENSIONS OF ROLLED SCREW THREADED REBARS

| Section number (nominal Ø of rolled products, dB) | da mm | h mm | dr mm | t mm | b mm | Δ mm | a deg. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| nom. | dev. | nom. | dev. | nom. | dev. | nom. | dev. | b mm | Δ mm | a deg. | |

| 14 | 13.5 | '+0.1 -0.2 | '+0.1 -0.2 | 13.0 | '+0.2 -0.3 | 4 | ±0.2 | 1.5 | ±0.2 | 90° | |

| 15 | 14.8 | '+0.2 -0.1 | 1.2 | '+0.2 -0.1 | 14.6 | '+0.2 -0.4 | 10 | ±0.2 | 4.8 | 90° | |

| 16 | 15.9 | '+0.15 -0.25 | 1.0 | '+0.15 -0.25 | 15.7 | '+0.2 -0.6 | 7 | 3.8 | |||

| 18 | 17.4 | ±0.35 | 1.4 | ±0.35 | 17.1 | '+0.3 -0.6 | 7 | 4.5 | 80° | ||

| 20 | 19.3 | ±0.4 | 1.3 | ±0.4 | 19.0 | '+0.4 -0.6 | 8 | 4.5 | 80° | ||

| 22 | 21.3 | ±0.4 | 1.3 | ±0.4 | 20.8 | ±0.5 | 8 | 4.5 | | ||

| 25 | 24.3 | ±0.4 | 1.8 | ±0.4 | 23.8 | ±0.5 | 14 | 6.5 | |||

| 26.5 | 26.3 | ±0.4 | 1.7 | ±0.4 | 25.8 | ±0.5 | 13 | 6.2 | 90° | ||

| 32 | 31.6 | ±0.4 | 1.9 | ±0.4 | 31.2 | '+0.6 -0.8 | 16 | 7.4 | 90° | ||

| 36 | 35.6 | ±0.4 | 2.0 | ±0.4 | 35.2 | '+0.6 -0.8 | 16 | 8.4 | |||

| 40 | 39.6 | ±0.4 | 2.2 | ±0.4 | 39.2 | '+0.6 -0.8 | 20 | 8.4 | | ||

STEEL CHEMICAL COMPOSITION:

| Steel Grade | Carbon | Manganese | Silicon | Vanadium | Titanium | Chromium | Sulfur | Phosphorus |

|---|---|---|---|---|---|---|---|---|

| St3 | 0.14-0.22 | 0.4-0.65 | 0.05-0.17 | – | – | 0.30 | 0.050 | 0.040 |

| 25G2S | 0.20-0.29 | 1.20-1.60 | 0.60-0.90 | – | – | 0.30 | 0.045 | 0.040 |

| 35GS | 0.30-0.37 | 0.80-1.20 | 0.60-0.90 | – | – | 0.30 | 0.045 | 0.040 |

| Steel 76 | 0.74-0.84 | 0.75-1.25 | 0.18-0.55 | – | – | – | 0.045 | 0.035 |

Mechanical Properties

| Plasticity category | Rolled product class | Electric heating temperature, °C | Yield strength σT(σ0.2), N/mm² | Ultimate tensile strength σB, N/mm² | Ratio of actual values σp/σT, (σ0.2) | Relative elongation, % | ||

|---|---|---|---|---|---|---|---|---|

| σₛ | σₚ | σₘₐₓ | ||||||

| Cₘᵢₙ | ||||||||

| Standard | A400 | '- | 390 | 590 | '- | 16.0 | — | 5.0 |

| Standard | A500 | '- | 500 | 600 | 1.05 | 14.0 | 2.0 | 2.5 |

| Standard | A600 | '- | 600 | 700 | 1.05 | 12.0 | 2.0 | 2.5 |

| Standard | A800 | 400 | 800 | 1000 | '- | 8.0 | 2.0 | 2.5 |

| Standard | A1000 | 450 | 1000 | 1250 | '- | 7.0 | 2.0 | 2.5 |

Dimensions des for 76 Steel Tie Rod - 9 Degrees Ø15.1mm

| Code | L (m) | Kg/pc |

|---|---|---|

| 9D600 | 6.00 | 8.50 |

| 9D500 | 5.00 | 7.08 |

| 9D400 | 4.00 | 5.67 |

| 9D300 | 3.00 | 4.25 |

| 9D200 | 2.00 | 2.83 |

| 9D150 | 1.50 | 1.42 |